Group of Companies

- Home

- Corporate Overview

- Group of Companies

KESM Industries Berhad “KESM” commenced its burn-in business in 1978 in Kepong, Selangor Darul Ehsan. Due to rapid business growth, it relocated from Kepong to Sungei Way Free Industrial Zone in Petaling Jaya, where the operations remain today. In 1983, the founders expanded its business in Malaysia by incorporating KESP to undertake the “burn-in” business in Bayan Lepas Free Industrial Zone, Penang. In 2021, another factory was set up in Malacca to support future growth in burn-in and test of automotive chips.

Burn In Equipment Capability

| Item | Equipment | Model | package |

Loading / Un-loading

|

| 1 | BI Oven | CCHV, CC1, CC3, CC4, KV, Wakefield | All | - |

|

2

|

Auto Loader/ Un-loader

|

FT2100, FT2300 | TSSOP / SOIC | Tube / Tube |

| FT4500, FT5800, FT7100, PPLU800, TY300 | LQFP / QFN / BGA | Tray / Tray | ||

|

3

|

Scanner

|

ICOS T120, ICOS 9450 | LQFP / QFN / BGA | Tray / Tray |

| Ismeca NY20, EXIS Tech Exis250, STI Gravity | TSSOP / SOIC | Tube / Tube |

Introduction of KESM Test (M)

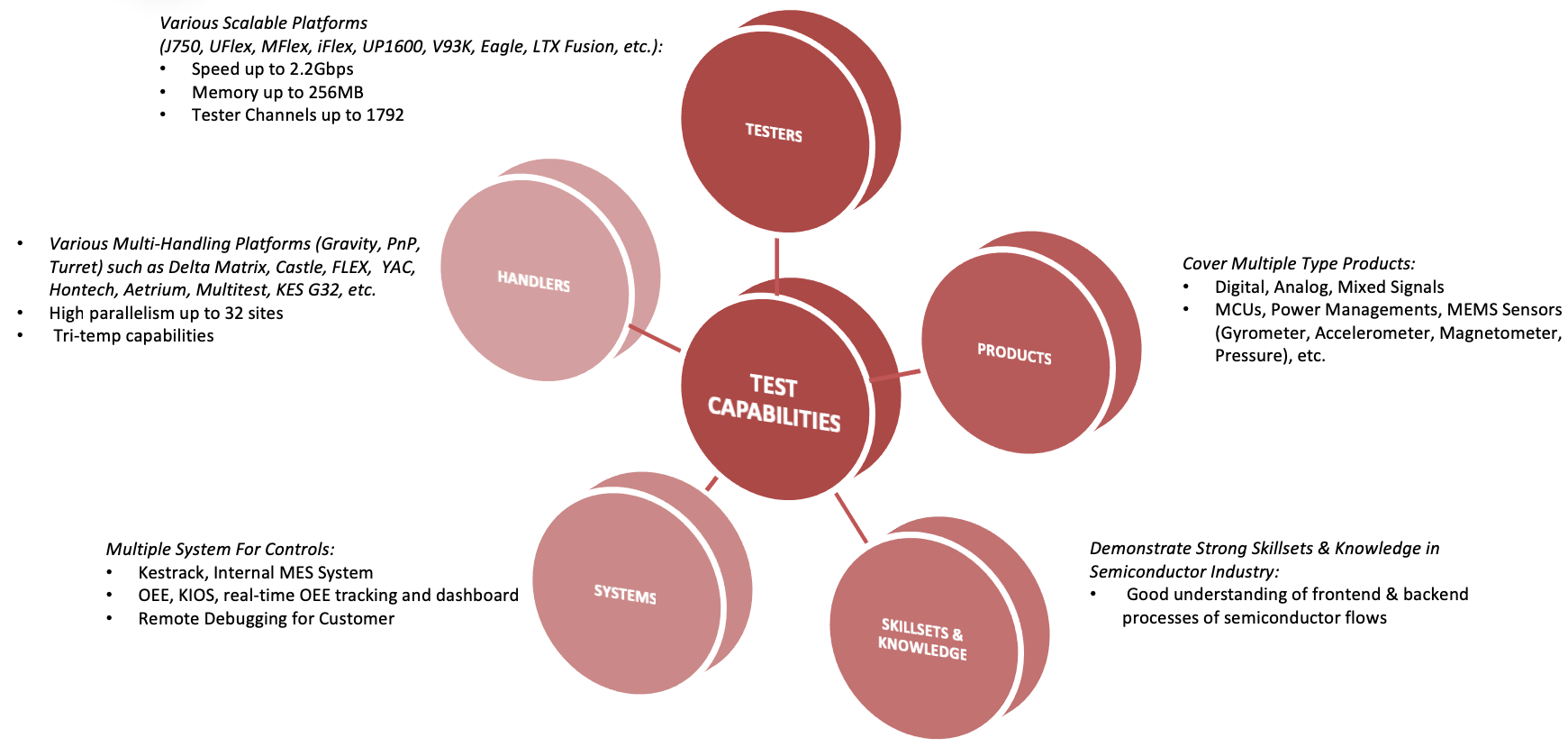

KESM Test (M) Sdn. Bhd. “KTM” was set-up as a semi conductor final test facility to add value in services to customers worldwide, and commenced operations in December 1995. Final Test is a very key area because of its critical testing process can sort out the tested good and reject unit and determine the electrically good parts to be shipped out via the test results. More than decades of knowledge gathered, KTM recognize test solutions are necessity attend to advance technology, performance, quality and cost of test.

We have extensive experience and capabilities in supporting all semiconductor core product types such as Digital, Analog, Mixed Signals, MCUs, Power Management and MEMS Sensors (Gyrometer, Accelerometer, Magnetometer, Pressure). Our test solutions include final testing (cold, ambient and hot), SLT, O/S test, TBE and MCU. Our test engineering team do provides test strategy solutions to our customers enabling them to focus on their products instead troubleshooting test hardware, software and other test issues.

Additionally, our test development team are work closely with customers for program conversion projects (single to multi-sites, temperature migration, tester platform migration), test cost reduction and test program coverage and optimization. We committed to offer test solutions beyond our customer’s expectations. KTM has a wide-ranging of equipments and continues to invest in new technology and capabilities to support latest product technology. Our flexible manufacturing strategy helps ensure we can consistently deliver the quality products on time.

KESM Tianjin Milestone

In 2007, KESM established a factory, KESM Industries (Tianjin) Co., Ltd, in the province of Tianjin, China, to provide semiconductor burn-in and test services.

Won Xiqing Outstanding Company Award in Year 2015 & 2016 consecutively.

KESP, Burn-In and Manufacturing Service Company, Penang, Malaysia

KESP Sdn. Bhd., a wholly-owned subsidiary of KESM and is a world-class Manufacturing Services provider located in Penang Free Industrial Zone, Malaysia.

Founded in 1983 as the IC Burn-In Services provider, we have provided uncompromised manufacturing services to market leaders in the semiconductor and electronics industries. In 1997, KESP diversified into Electronics Manufacturing Services “EMS” covering LED Lighting Assembly, SMT/COB Assembly, Box Build & System Integration.

We believe in building long term strategic partnership through our commitments in QCD (Quality, Cost and Delivery). We provide reliable IC/LED Burn-In Services, quality LED Lighting Assembly Services and One-Stop Solution Integrated EMS.